Introduction

Brazing is a metal joining process whereby a filler metal is heated above the melting point and distributed between two or more close fitting parts by capillary action. The filler metal is brought slightly above its melting ( liquidus ) temperature while protected by a suitable atmosphere, usually a flux. It then flows over the base metal ( know as wetting ) and is then cooled to join the workpieces together. It is similar to soldering, except the temperatures used to melt the filler metal are higher.

Tungsten carbide parts are usually connected to steel and other materials by brazing. Brazing involves placing a metal brazing alloy together with flux between the parts to be connected, and then heating the assembly until the brazing alloy melts and flows to completely fill the small gap between the two parts.

Brazing Alloy

Under normal conditions, all common brazing alloys from pure copper to silver alloys will easily wet the cemented carbide surface. Popular brazing alloys (shown in parentheses are the name of the American Welding Society) are composed of approximately 50% silver, including cadmium (BAg-6), cadmium-free (BAg-24), and manganese (BAg-22) And tin alloy (BAg-7). These alloys have a melting point between 1150℃ and 1300℃.

For high temperature applications, copper is usually used as a brazing material. Although the tensile strength of copper is lower than that of silver alloys at room temperature, copper can still maintain most of its strength at temperatures close to 1000℃. If brazing is performed in an oxidizing environment, borax is a copper flux. However, generally, copper brazing is performed in a hydrogen atmosphere that does not require flux. Other high-temperature brazing includes high-nickel alloys that contain some chromium, boron, and silicon. The flow temperature of these alloys exceeds 1800℃. It should be noted that higher brazing temperatures may cause grain growth or other undesirable changes in steel parts.

Considerations for successfully brazing tungsten carbide:

-Brazing preparation is a key concern. Oils and other contaminants like surface oxidation on the carbide and steel components can prevent a good bond from forming.

-Wetting of the carbide by the braze alloy.

-Managing the stresses caused by differential expansion and contraction rates of parent materials

Furnace brazing

Furnace brazing is a semi-automated process by which metal components are joined using a dissimilar lower filler metal.Vacuum brazing furance is an equipment that allows design and manufacturing engineers to join simple or complex designs of one joint or multi-joint assemblies in the condition of controlled vacuum atmophere.

– Vacuum brazing, because no flux is used, significantly improves the corrosion resistance of the product, avoids all kinds of pollution, pollution-free processing equipment costs, and has good safe production conditions;

– Vacuum brazing not only saves a lot of expensive metal flux, but also does not require complex flux cleaning procedures, reducing production costs;

– Vacuum brazing solder has good wettability and fluidity, and can weld more complex and narrow channel devices. Vacuum brazing improves product yield and obtains a sturdy and clean working surface;

Induction brazing

Induction brazing is a very adaptable process for joining carbide tips, particularly within a production environment. Induction brazing has many advantages over other common heating methods. Reasons to consider using induction heat include:

-Quick, rapid heating

-Controlled, precise heat control

-Selective (localized) heat

-Production line adaptability and integration

-Improved fixture life and simplicity

-Repeatable, reliable brazed joints

-Improved safety

Our Advantages

Brazing is a successful and reliable way of joining carbides to steel used in many applications including cutting tools, mining picks,punches, dies, etc.SANWU has over ten years of expertise in tungsten carbide brazing, using processes such as torch, induction and furnace brazing.Our advantages:

- We cooperate with the best the raw material suppliers in China

- Unique Corrosion Resistant Braze Alloy improves strength and decreases corrosion rate

- Optimum braze in a region prone to crevice corrosion

- Unique alignment feature provides a consistent braze gap, carbide orientation, and increases shear strength.

- Excellent Braze Coveragea,Our proven brazing technology and experienced workers resulting in a virtually void free bond between carbide and steel.

- Provide reliability in the harshest, most abrasive conditions

- Strict QC system

- Strong and stable packaging for large products to avoid tools damage during transportation (oil paper +foam+ wooden case)

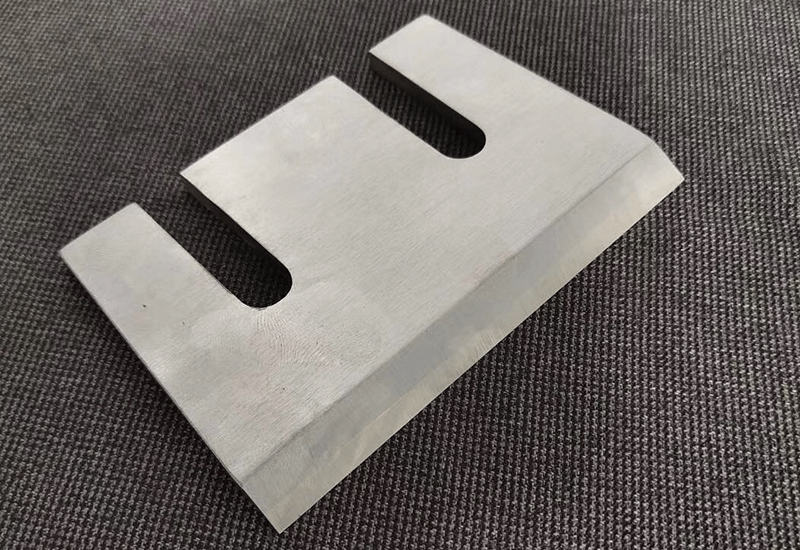

Sanwu carbide inlay blades allow our customers to achieve the full benefit of carbide at a fraction of the cost of solid carbide blades.

Quality Control

Our quality assurance and validation steps include:

- 100% visual inspection of external braze joint and of carbide

- Ultrasonic C-Scan of braze joint

- ASTM G65 Procedure A – Abrasive Wear Testing

- Microstructure Evaluation of braze joint

- Corrosion Testing – Gravimetric and Potentiostatic methods

- Salt Water Immersion Testing

- Rockwell Hardness Testing of Steel Backer after brazing

TaiYuan Sanwu Tools Co.,Ltd

Add: No. 85 Zhengyang Street, Xiaodian District, Taiyuan City, Shanxi Province, China

Tel: +86-0351-7172172

Mobile: +86-18334702131

E-mail: Hale.liu@sanwutools.com

info@sanwutools.com

Web: https://sanwutools.com