Composition

Cemented Carbide is made up of carbide particles held together by a bonding agent.

The most important of them are:

- Tungsten carbide (WC)

- Titanium carbide (TiC)

- Tantalum carbide (TaC)

- Niobium carbide (NbC)

The bonding agent used is predominantly Cobalt (Co)

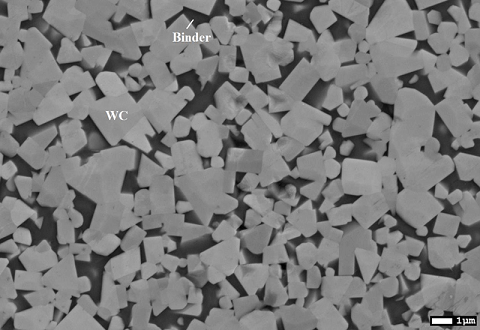

Structures of cemented carbide

Pure WC-Co hardmetals, so-called K types, were available right from the early days of hardmetal development, and were used predominantly for machining short-chipping cast materials. This is a two-phase hardmetal with a hard tungsten carbide phase (α phase) and that of the highly tenacious cobalt binding metal (β phase).

By mixing in other carbides such as titanium carbide, tantalum carbide and niobium, hardmetals with greater wear resistance – P types – were developed specifically for machining long-chipping steel workpiece materials.

Three-phase hardmetals were developed with an additional phase in titanium, tantalum and niobium carbides (γ phase).

By varying the grain size and the bonding agent, it is possible combine hardness and tenacity, whereby large grit sizes and a higher proportion of bonding agents increase the tenacity of hardmetals, while file grit sizes (fine-grained hardmetals) and a low proportion of bonding agent lend hardmetals a relatively high degree of hardness.

In this way, different hardmetal compositions and structures can address differing metal cutting conditions.

Cemented carbide properties and characteristics

Tungsten carbide (WC)

WC provides a high degree of hardness and wear resistance. Linking WC with cobalt at sintering temperature brings about good cohesion and a pore-free microstructure.

Titanium carbide (TiC)

Possesses a high degree of hardness and low diffusion tendency. TiC increases diffusion resistance, but demonstrates a reduced inner bond strength (tenacity) of the cutting material.

Tantalum carbide (TaC), niobium carbide (NbC)

Increases diffusion resistance. Tenacity, wear resistance and hot hardness are improved.

Cobalt (Co)

The cobalt content largely determines the tenacity of the hardmetal.

ISO classification of Cemented Carbide

The International Standards Organisation (ISO) has created a classification system for certain application fields. Here, workpiece materials to be machined are placed in opposition to the characteristics of hardmetal. in addition, they have been assigned different colours in order to simplify both the handling and the application of the materials.

ISO calssification of workpiece material:

Blue P denotes the machining of long-chipping materials such as steel, cast steel and stainless steel.

Yellow M denotes the machining of austenitic, stainless steel and heat-resistant materials.

Red K denotes the machining of short-chipping materials such as grey cast iron, malleable cast iron, nodular cast iron and vermicular-graphite cast iron.

Green N denotes the machining of aluminium and other non-ferrous metals, as well as non-metallic materials.

Orange S denotes the machining of high-temperature resistant nickel and cobalt alloys as well as titanium and titanium alloys.

White H denotes the machining of hardened steel, hardened cast iron materials as well as mould castings and manganese steel.

O (Other): Non-ISO. Thermoplastics, thermosets, GFRP (Glass Fiber Reinforced Polymer/Plastic), CFRP (Carbon Fiber Reinforced Plastic), carbon fiber composites, aramid fiber reinforced plastic, hard rubber, graphite (technical). Various industries are now using composites to a greater extent, especially in the aerospace industry.

Each group is subdivided into sub-groups from 01 – 50, whereby greater tenacity is required of the cutting edge as the numbers rise, while in descending numerical order greater wear resistance is required of the cutting edge.

Starting with Group 01, which includes materials for finishing work with high cutting speeds and low feed rates; Group 25 encompasses cutting speeds and feed rates for medium metal cutting, and so on upward to Group 40 / 50 for rough machining at low cutting speeds, with large removal cross-sections and changing machining conditions.

The subgroups of the ISO classification refer exclusively to the cutting material hardmetal and do not include ceramic, CBN or PCD cutting materials.

This classification is standardized in DIN/ISO 513.

Cemented Carbide Production Process

Raw Material

Hardmetal can only be manufactured by means of powder metallurgy.

The sourcing of raw materials and the energy-intensive processing methods help to make hardmetal raw materials relatively expensive.

Some hardmetal manufacturers start their production process with tungsten carbide powder in different grit sizes, others prefer to produce not only the carbide but also the metal from chemically pure tungsten compounds. Depending on the required hardmetal type, the necessary quantities of tungsten carbide with a defined grit size characteristic, complex carbides of a defined composition and cobalt are precisely weighed and prepared for milling.

The wet milling method used exclusively today serves to transform the powder constituents into an ultra-finely dispersed conglomerate. After the milling process, the wet sludge is passed through a sieve and the milling fluid and powder separated. As filling the press mould when using automatic pressing processes calls for particularly good pourability in the powder, the dried powder must subsequently be transformed into granulate. The pressing agent (e.g. 1-2% paraffin wax) is generally added during the course of drying.

Pressing of cemented carbide powder

The manufacture of hardmetal parts begins with moulding by hand (hand forming) or moulding using pressing dies.

The efficient method of moulding is direct pressing in pressing dies in high-speed automatic mechanical or hydraulic presses.

The filling of press moulds naturally calls for powders with particularly good pouring properties.

As a result of pressing in single or double-sided automatic presses, the blank is given its basic shape, but not the measurements it is required to demonstrate in its sintered state. This type of “compact” has a porosity (shrinkage) of appr. 50 % by volume, which disappears completely after the sintering process. The linear shrinkage factor for the width, height and length dimension is between 17 and 20%.

These dimensions must be taken into consideration as early as the design of the press dies (male and female die).

As the carbides used (WC, Ti, Ta, Nb) do not have plastic deformation capability, the pressing forces are between 1.5 – 1.8 tons per cm2 (150 – 180 MPa). The benefit of the pressing method for producing hardmetals is the ability for direct moulding and also the achievable piece numbers at between 15 and 20 strokes per minute. Alternative methods are: Injection moulding, extrusion pressing, cold isostatic pressing.

Hardmetal sintering

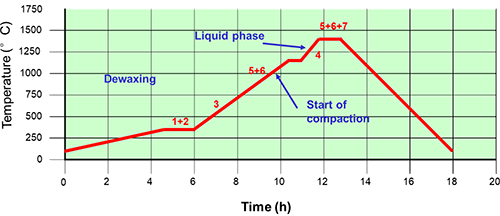

Sintering requires first and foremost precise temperature regulation, process sequence times and a suitable atmospheric environment in order to complete the enormous transformation from a porous powder compact to a dense hardmetal blank and so to the best possible cutting material available.

The compacts prepared ready for sintering on graphite plates are placed in the sintering oven. Initially during the heating-up process, the compacts reach the critical range at which the pressing aid (paraffin) is expelled. The sintering process must be precisely temperature and time controlled in order to ensure that the produced carbide demonstrates the required characteristics.

During the sintering process, a reaction occurs which is called liquid phase sintering, meaning that on reaching the relevant prescribed sintering temperature of 1350 to 1500°C, the bonding agent (cobalt) is melted and a not insignificant quantity of carbide has dissolved.

The capillary forces which occur during sintering cause the pores to close, while the powder grains join primarily as a result of diffusion.

Sintering requires first and foremost precise temperature regulation, process sequence times and a suitable atmospheric environment in order to complete the enormous transformation from a porous powder compact to a dense hardmetal blank and so to the best possible cutting material available.

The compacts prepared ready for sintering on graphite plates are placed in the sintering oven. Initially during the heating-up process, the compacts reach the critical range at which the pressing aid (paraffin) is expelled. The sintering process must be precisely temperature and time controlled in order to ensure that the produced carbide demonstrates the required characteristics.

During the sintering process, a reaction occurs which is called liquid phase sintering, meaning that on reaching the relevant prescribed sintering temperature of 1350 to 1500°C, the bonding agent (cobalt) is melted and a not insignificant quantity of carbide has dissolved.

The capillary forces which occur during sintering cause the pores to close, while the powder grains join primarily as a result of diffusion.

Temperature-time progression during sintering

- Dewaxing phase

- Homogenization

- Dissolution of carbides in the binding phase

- Formation of the liquid phase (binder metal); new arrangement of carbide grains

- Compaction, shrinkage

- Grain growth process

- Degradation of interfacial energy due to re-arrangement process of individual grains

Hardmetal machining

SANWU hard machining service includes:

- Wire Cutting

- Centerless Grinding

- Chamfer or Round Grinding

- Internal Grinding

- CNC Grinding

- Plain Surface Grinding

- Thread Grinding

- Five-Axis Grinding

- Electrical Discharge Machining (EDM)

- Surface Passivation

- Surface Polishing

- Laster Marking

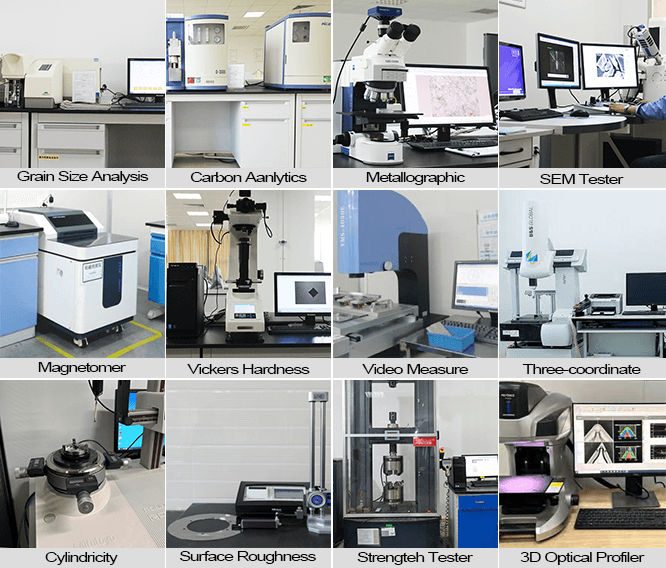

Inspection

Behind the outstanding quality,delivery and customer service,Strictly quality control is must.The physical and chemical properties of

tungsten carbide require

continuous quality testing

throughout the entire

manufacturing chain.

Inspection items include.

- Grain Size distribution

- Oxygen&Carbon Analytics

- Metallography

- Magnetic Saturation

- SEM Tester

- Hardness

- Dimension

- Surface Roughness

- Density

- Coercivity

- Flexural strength

- Tensile strength

- Compressive strength

- Impact toughness

- Fatigue strength

- Product Performance

Base hardmetals and substrates

Base hardmetals (classical hardmetals):

Uncoated hardmetals are an established cutting material for all applications where extreme cutting edge sharpness or tenacity are paramount.

Ultra-fine grained hardmetals:

Ultra-fine grained hardmetals are superior to conventional hardmetals in terms of their hardness, edge strength and flexural strength, but quickly display plastic deformation tendencies under thermal stress.

Hardmetal substrates:

Impact resistance and bending strength call for a high cobalt or binding metal content. However, this can exert an unfavourable effect on compressive strength and high temperature resistance.

Today, the combination of substrate and coating provides us with the basis for hardmetal types adjusted in line with their specific application.

Coating of hardmetals

Modern coated hardmetal types have improved substantially in terms of their reliability and efficiency since the introduction of the first coated hardmetals (around 1970).

The underlying concept of an extremely tenacious core (substrate) surrounded by an extremely hard coating has meant a radical increase in both cutting speeds and also the service life of tools over recent decades.

The most frequently used coating processes are:

- CVD (chemical vapour deposition)

- PVD (physical vapour deposition)

For metal cutting, due to their higher stock removal rates, thicker CVD coatings are used predominantly for drilling, turning and milling, while thinner PVD coatings offer benefits where metal cutting operations call for sharp coated cutting edges or particularly high tenacity.

CVD coating structure

Several layers of different hard materials are deposited on the hardmetal substrate during the CVD process.

The customary hard material layers are:

– Titanium carbide TiC,HV3200,Gray

– Titanium nitride TiN,HV2300,Golden

– Titanium carbon nitride TiCN,HV2800,Brown ash

– Aluminium oxide Al2O3,HV3000,Transparent

-Titanium Aluminum Nitride,,HV3100,HV3100,Violet blue

PVD Coating

Depending on the application, the layer combination and layer thickness are varied and coordinated to ensure the optimummaterial

for each application.For many years, the coating of hardmetals remained the domain of the (high and medium temperature) CVD processes.Today, the PVD process has also become established as a supplementary coating process alongside CVD coating.Reduction of the coating temperature to appr. 450°C for PVD processes exerts practically no influence on the tenacity properties of the substrate (base hardmetals) during the coating process. The 2 – 5 µm thick hard material coatings, generally titanium based, serve to seal the surface and prevent reactions between components of the hardmetal and the steel materials during metal cutting processes.

The PVD process has become an established feature of the metal cutting market particularly for the coating of highly profiled and

extremely sharp metal cutting tools such as indexable inserts for machining aluminium alloys, cylindrical milling and drilling tools,

as well as for multiplayer applications demonstrating extremely high levels of tenacity.

Compared CVD with PVD

TaiYuan Sanwu Tools Co.,Ltd

Add: No. 85 Zhengyang Street, Xiaodian District, Taiyuan City, Shanxi Province, China

Tel: +86-0351-7172172

Mobile: +86-18334702131

E-mail: Hale.liu@sanwutools.com

info@sanwutools.com

Web: https://sanwutools.com